Onsite Machining

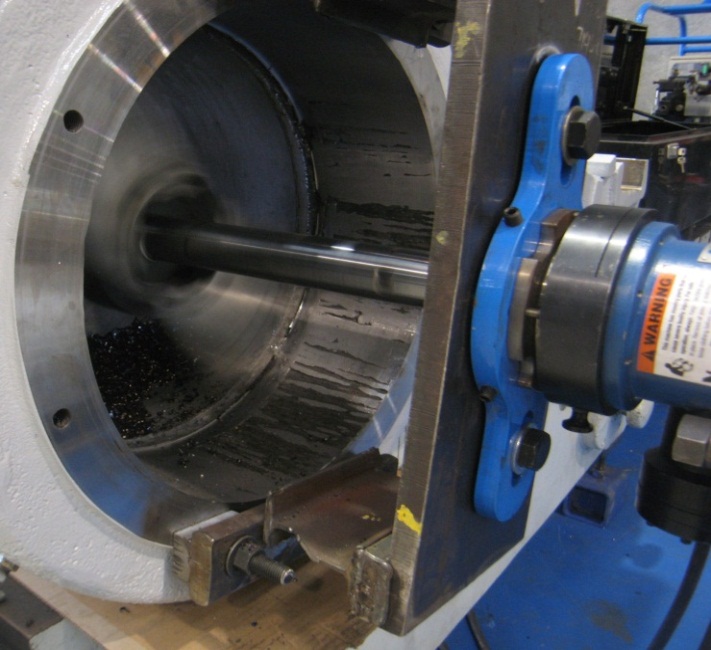

Safe, cost-efficient operation of mine sites and industrial plants regularly necessitates field machining, and often the work needs to be completed urgently to return the plant to service as quickly as possible. With a wide range of onsite machining equipment and specialist machinists ready to act, Impact Engineering consistently impresses its customers with its rapid turnaround time and quality of works.

Due to its very nature, field machining often requires innovation and adaption to achieve the end result. Our depth of experience in site machining combined with our embedded engineering ensures modifications are made safely, effectively and quickly.

Key capabilities include –

|

|

|

|

|